Polyamide 6 and copolyamides for food containers

Currently, the challenges in food packaging design are aimed at extending the shelf life of food and ensuring optimal mechanical behavior throughout the distribution chain, while providing an attractive design for consumers.

Promyde polyamides are used in the packaging industry for their excellent mechanical properties, barrier properties and for providing a quality finish thanks to their high gloss and transparency.

Promyde has extensive experience in the manufacture of PA6 for food barrier packaging. In order to meet the increasingly demanding technical and sustainability requirements of the packaging industry, NUREL, over the last few years, has focused its innovation efforts on developing a complete range of copolyamides with unique performance in the packaging market.

Let's define the packaging you wish to replace

What is the sustainable challenge your packaging needs to overcome?

we will propose you a REAL solution that will adapt to all your requirements

Are you ready to turn your packaging in a REAL sustainable solution?

Copolyamides with improved properties

Our R&D department has developed a series of copolyamides that complement the functionality of conventional PA6, providing solutions highly demanded by the packaging industry:

- Deep thermoforming solutions

- Polyamides that eliminate curling in asymmetrical structures

- Low temperature sealable polyamides

- High puncture and breakage resistance

- Oxygen barrier solutions

- Transparent polyamides that allow pasteurization and retort

- Vacuum packaging shrink film

Polyamide for film extrusion adapted to every requirement

PROMYDE polyamides and copolyamides can be adapted to different extrusion processing methods, such as blown extrusion, triple bubble extrusion, cast extrusion and bioriented polyamide or BOPA.

In addition, NUREL works in collaboration with film manufacturers and packagers in the redesign of food packaging, analyzing the materials currently used and the specific requirements of each application.

Sustainable polyamide packaging

The European Strategy 2030 on reducing the environmental impact of plastic waste indicates that packaging should be 50% reusable or recyclable by 2025, 55% by 2030, reaching 60% by 2035. Moreover, less than 10% of plastic waste should be landfilled.

NUREL proposes to face this challenge in 4 different ways, with solutions for 100% recyclable packaging, with proposals for lighter packaging, bio-based packaging and with solutions for compostable packaging.

Solutions

Barrier solutions

We have two new and innovative food packaging solutions to improve the oxygen barrier and permeability properties of polyamides.

Sealing films

Specially designed for the production of thermoforming films and vacuum bags, Promyde's portfolio includes sealable copolyamide with low sealing temperature.

High resistance films

Designed for the packaging of bone-in meat products in multilayer structures, Promyde improves resistance to tearing and puncture while maintaining optimum gloss and transparency.

Active packaging

Active packaging technology incorporates active ingredients encapsulated in the polymer to provide antioxidant and antimicrobial properties, extending the shelf life of packaged foods.

Soluciones antivirales

Applicable to all types of polymers, VI_SAFE minimizes the risk of virus transmission by contact with surfaces.

Film delamination

Thickness reduction

Thanks to the high barrier performance of our Promyde copolyamides, the amount of polyamide in multilayer or monolayer structures can be reduced.

Recycled

Recyclable

Biobased

BIODEGRADABLE

Applications

Stand-up pouches

NUREL offers a complete range of Polyamide 6, Copolyamides and Ultra-High barrier materials for Doypacks. PA-based film materials not only help extend the shelf life of packaged food but also contribute to reducing plastic usage. Promyde polyamides offer excellent mechanical and barrier properties while providing an appealing packaging finish, thanks to their glossy appearance.

Vacuum Packaging

PA vacuum bags are commonly used to vacuum pack meats, fish, vegetables, cheese and prepared foods. Vacuum sealing helps to extend the shelf life of these products by preventing the growth of microorganisms that cause spoilage.

Deep thermoforming

Deep thermoformed packaging is extensively utilized nowadays due to its numerous benefits, including lightweight, transparency, and gas barrier properties, necessitating the use of materials with high technical performance for its production.

Cheese packaging

Cheese packaging is essential to guarantee the quality, safety, and freshness of the product. It must meet a series of requirements to protect the cheese from oxidation, dehydration, and preserve its maturation process. NUREL offers solutions that adapt to these requirements by providing packaging with barrier properties and oxygen permeability.

Pasteurized and retort packaging

These containers are designed to withstand pasteurization and retorting processes, which are food preservation methods involving high temperatures and pressures, for which our latest generation copolyamides are the ideal material.

Oven bags

Promyde PA offers heat-resistant grades for films used in baking bags and oven-safe vacuum skin packaging (VSP). These materials are perfect for cooking moist, tender meat and vegetables and have been validated for use in food cooking for up to 4 hours at temperatures of up to 205°C.

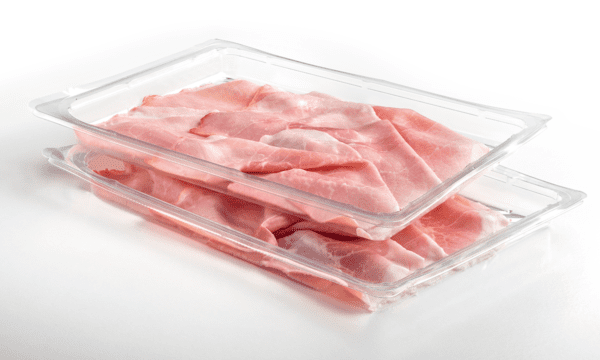

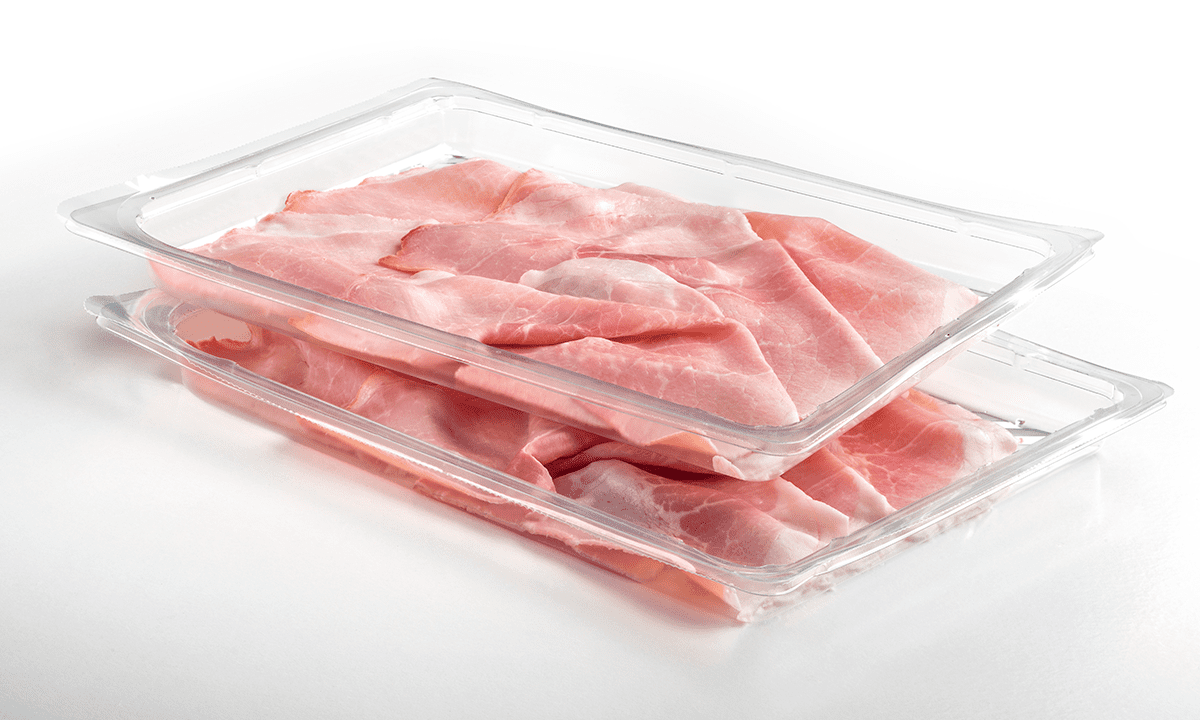

Lids and trays

NUREL offers a wide range of PA products to ensure performance in the most challenging MAP trays for food packaging, such as fresh fish and meat. Sealability, thermoforming performance, brightness, and barrier requirements are assured.

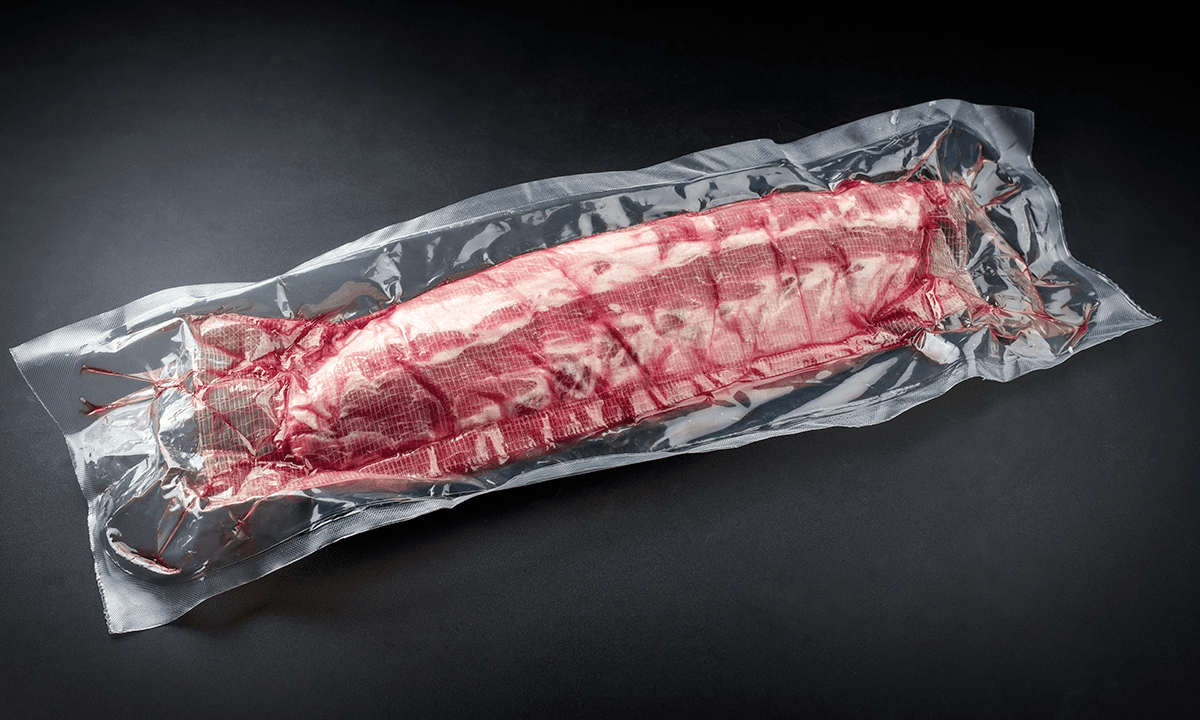

Meat and bone-in meat packaging

Packaging for sharp-edged foods requires high puncture resistance, flexibility, moisture barrier, transparency, and an attractive gloss. NUREL offers a range of special copolyamides and polymers with high oxygen barrier properties for the manufacturing of vacuum bags and thermoformed packaging for meat.

Skin Packaging

Skin packaging is gaining popularity due to its lightweight and visually appealing design, as well as its superior technical performance. NUREL provides specially formulated copolyamides that exhibit exceptional strength, sealing capabilities, barrier properties, and unmatched glossiness.

Casing for sausages and sausage products

NUREL offers a specific range of Promyde PA 6 designed specifically for casing applications, as well as a new product range of ultra-high barrier polymers called Enoxite, to extend the shelf life of sausages and cooked meats

Fish and seafood packaging

For those fish and seafood packages that need specific characteristics, NUREL offers different alternatives in PA6 and Copolyamides that allow extending the shelf life of these foods.

Frozen food products

For frozen food products, Promyde copolyamide Enoxite ultra high barrier materials are a perfect fit. They are compatible with freezer storage and help prevent freezer burn of Fish and meat.

RELATED MARKETS

PROCESSES

Want to stay updated on the latest on NUREL Technical Polymers?

Subscribe to the Newsletter